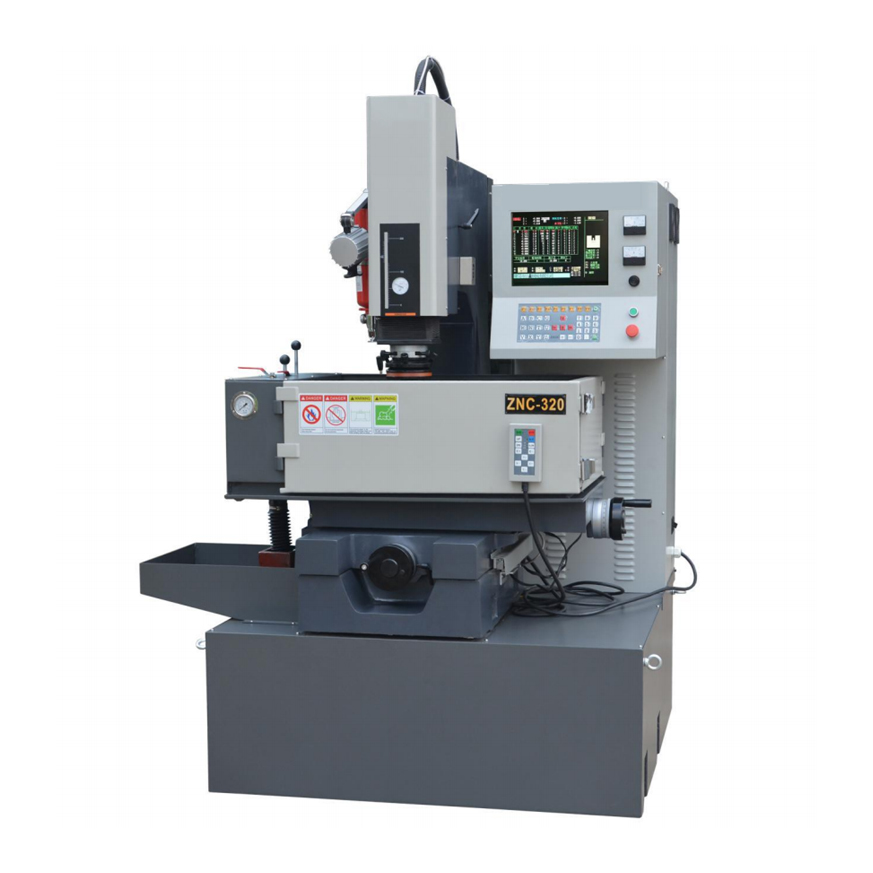

Die Sinking Edm Machine ZNC320 450 550 650

Machine Introduction:

1.Machine body structure with advanced castings of resin sand stress relieving.

2.Adopting precision CAD design and high precision frame structure.

3.X,Y axles movement surface with "TURCITE" and ball screw.

4.X,Y axles are made up V-shape and plane structure,ensuring the precision life of mechanical.

5.Adopting Japan SANYO DC servo motor,linear bearing and high strength and precision of integral castings.

6.Using high frequency induction hardening heating treatment.

7.The table which is precision grinded work table.

8.Using centrifugal high pressure oil pump of WALRUS and 10u filter system.

9.The castings are stress relieving cast iron.

10.The desktop uses high frequency quenching.

11.X,Y axles adopts the screw nuts of "model steel "which is produced by Taiwan.That may install ball screw optionally.

12.With functions of large area process and deep holes process.

13.X,Y axles adopt imported or the same level of ball screw.

14.Import accessories including electrode tip,automatic fire extinguisher,lamps,hand pull pump,page switch,gasket and centimeter bring up competitive machine tools.

Functions:

1).Intelligent compile:depending on experience or input electric current and depth of processing.

2).Sectioned automatically from thick to thin.The steps which may complete the processing at one time from thick→middle→thin to sleek.

3).Setting copper pairs with steel,graphite pairs with steel and copper pairs with hard alloy according to the electrodes and materials.

4).Multiple set selections to process the thin slice and large-sized workpieces.

5).Anti-carbon automatically detection.

6).Fire prevention and liquid level control automatically.

7).Translating between Chinese and English,metric and imperial.

8).Conform to the CE safety standard of power box.

| Model number | ZNC 320

(=ZNC 350) |

ZNC 450 | ZNC 550 | ZNC 650 |

| Workbench size(mm) | 600*300 | 700*400 | 800*480 | 1000*600 |

| Working slot size(mm) | 820*500*300 | 1120*620*420 | 1290*770*500 | 1700*1000*620 |

| X-Y-Z travel(mm) | 300*200*200 | 400*300*200 | 500*400*250 | 600*500*250 |

| Spindle head stroke(mm) | 200 | 200 | 300 | 300 |

| Electrode lifting weight(kg) | 60 | 70 | 200 | 200 |

| Max. workpiece weight(kg) | 500 | 750 | 1500 | 2250 |

| Electrode plate to table distance(mm) | 150-550 | 200-600 | 160-710 | 260-860 |

| Working fluid capacity(L) | 280 | 300 | 470 | 940 |

| Dimension(mm) | 1320*1220*2240 | 1400*1200*2050 | 1530*1850*2250 | 2150*1800*2400 |