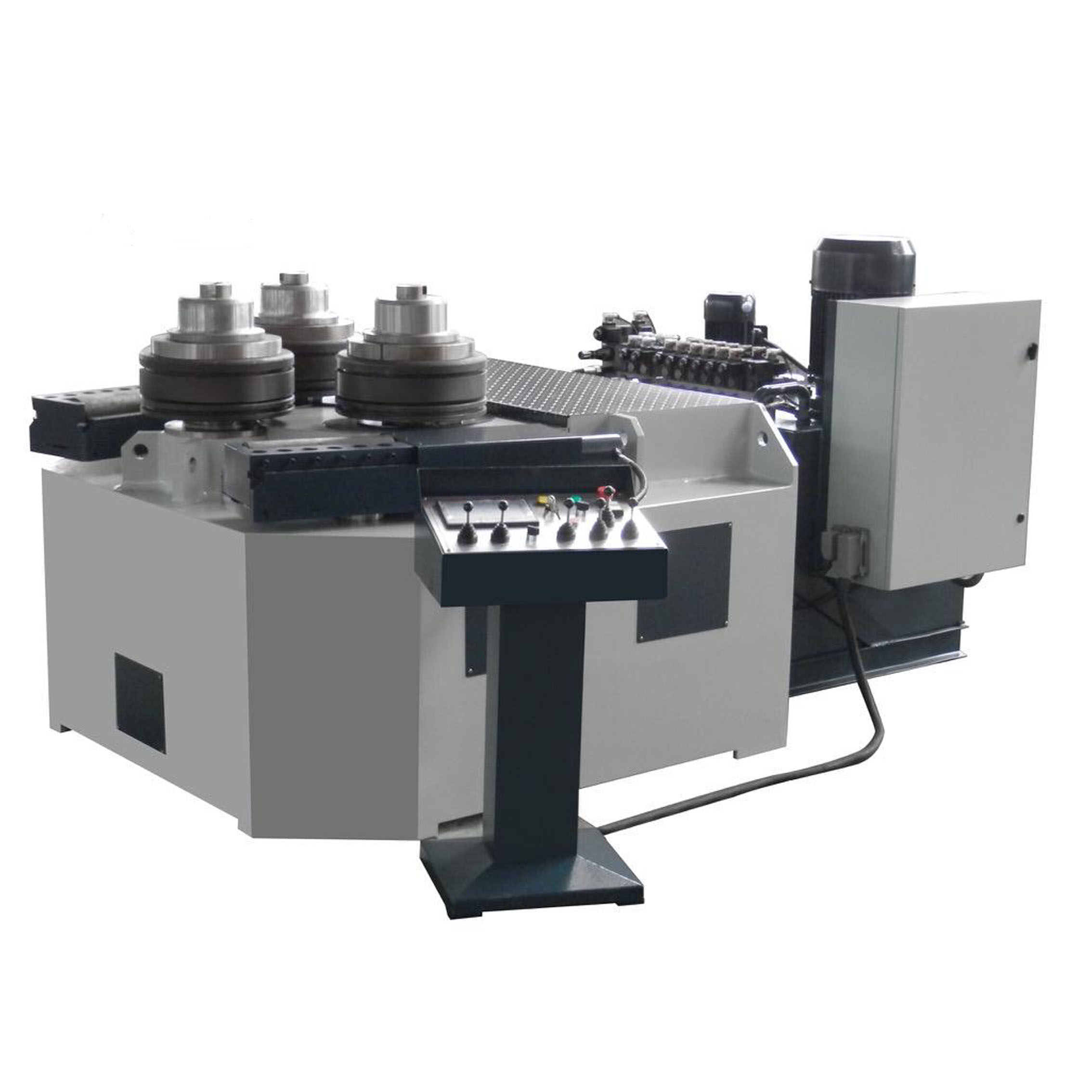

Profile Bending Machine W24-75 W24-100 W24-140

Product Application

The material winding machine produced by our company is specially used for crimped angle steel, channel steel, i-steel, flat steel, side steel, round steel, etc., various types of strip efficient processing equipment, and can be used for primary winding and correcting round operation procedures. Widely used in petroleum, chemical, hydropower, shipbuilding and machinery manufacturing.

The two bottom rollers of the machine are mainly the drive rollers. Three main work roll drive rollers, fixed center ritation vibrator for rotating the rollers on both sides, roller device on both sides, which is beneficial to ensure the asymmetrical part of the forming volume quality winding. The structure of the machine is advanced and reliable, small in size and function. Complete, is the current equipment at home and abroad. The machine can be equipped with advanced general-purpose or special-purpose molds, which is easy to operate and high in efficiency, and is well received by customers.

| Model | W24-75 | W24-100 | W24-140 | |

| Max.bending resistance of section modulus(cm3) | 75 | 100 | 140 | |

| Bending speed(m/min) | 5 | 5 | 5 | |

| Material yield limit(Mpa) | 250 | 250 | 250 | |

| Angle-steel in-turn | Max. Section(mm) | 100x10 | 120x12 | 140x16 |

| Min. Bending dia(mm) | 2000 | 2500 | 2400 | |

| Angle-steel out-turn | Max. Section(mm) | 120x12 | 140x16 | 150x16 |

| Min. Bending dia(mm) | 1600 | 1800 | 2200 | |

| Channel steel out-turn | Max. Section(mm) | 25 | 28 | 30 |

| Min. Bending dia(mm) | 1100 | 1700 | 1200 | |

| Channel-steel in-turn | Max. Section(mm) | 25 | 28 | 30 |

| Min. Bending dia(mm) | 1600 | 1700 | 1700 | |

| Channel-steel side-turn | Max. Section(mm) | 12.6 | 14.6 | 16 |

| Min. Bending dia(mm) | 2000 | 2500 | 300 | |

| Flat steel horizontal turn | Max. Section(mm) | 220x40 | 250x40 | 280x50 |

| Min. Bending dia(mm) | 1000 | 1200 | 1300 | |

| Flat steel vertical turn | Max. Section(mm) | 110x40 | 120x40 | 150x40 |

| Min. Bending dia(mm) | 1100 | 1300 | 1500 | |

| Round steel bending | Max. Section(mm) | 85 | 90 | 100 |

| Min. Bending dia(mm) | 1000 | 1100 | 1200 | |

| Round tube bending | Max. Section(mm) | 114x5 | 159x5 | 168x6 |

| Min. Bending dia(mm) | 1200 | 2000 | 2000 | |

| Square tube bending | Max. Section(mm) | 90x8 | 100x10 | 125x10 |

| Min. Bending dia(mm) | 1600 | 2000 | 2500 | |

| I steel vertical bending | Max. Section(mm) | 10 | 12.6 | 14 |

| Min. Bending dia(mm) | 2000 | 2500 | 3000 | |